A walk-in freezer wiring diagram is a visual blueprint outlining electrical connections for safe and efficient operation. It ensures proper installation, maintenance, and troubleshooting of components like compressors and defrost timers, promoting reliability and compliance with safety standards.

1.1 Importance of Wiring Diagrams for Walk-In Freezers

Wiring diagrams are essential for installing, maintaining, and troubleshooting walk-in freezer electrical systems. They provide a clear visual representation of circuits, components, and connections, ensuring safe and efficient operation. These diagrams help technicians identify potential issues quickly, reducing downtime and ensuring compliance with electrical codes and safety standards. Regular inspections and updates to wiring diagrams are crucial for long-term reliability.

1.2 Overview of Key Components in Walk-In Freezer Wiring

Walk-in freezer wiring comprises essential components such as compressors, defrost timers, fan motors, and control modules. These elements are interconnected through robust junction boxes and tear-proof cable glands. The wiring diagram illustrates the circuit paths, ensuring power distribution and control signals are correctly routed. Proper insulation and adherence to electrical codes are critical for safety and efficiency in the system.

Understanding the Symbols and Notations

Walk-in freezer wiring diagrams utilize distinct symbols for components such as compressors and fan motors. These notations aid in understanding circuit pathways, crucial for accurate installation and maintenance.

2.1 Common Symbols Used in Walk-In Freezer Wiring Diagrams

Walk-in freezer wiring diagrams feature standardized symbols for components like compressors, motors, and control modules. These symbols represent electrical elements, ensuring clarity in understanding circuit connections and pathways for installation and troubleshooting purposes.

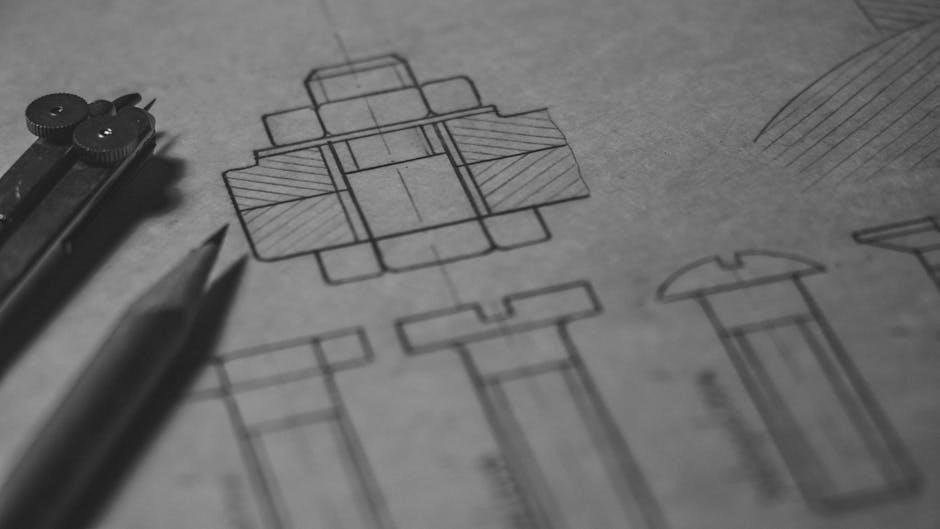

2.2 Interpreting Wiring Schematics for Walk-In Freezers

Interpreting wiring schematics for walk-in freezers involves understanding the layout and connections of electrical components. These diagrams guide technicians through circuit pathways, ensuring proper installation and troubleshooting. Symbols and labels clarify connections between compressors, motors, and controls, while sequences highlight operational flows, aiding in efficient and safe system management.

Electrical Components of a Walk-In Freezer

Walk-in freezers rely on key electrical components like compressors, fan motors, and defrost timers. These elements work together to regulate temperature and ensure efficient operation, as shown in wiring diagrams.

3.1 Compressor Motor and Thermal Overload Protection

The compressor motor is the heart of a walk-in freezer, driving the refrigeration cycle. Thermal overload protection ensures the motor shuts down during excessive heat, preventing damage. Wiring diagrams detail these connections, crucial for safety and efficiency, ensuring the system operates within safe parameters to avoid premature wear and potential hazards.

3.2 Defrost Timer and Control Modules

The defrost timer regulates the periodic thawing of ice buildup in the evaporator, ensuring efficient cooling. Control modules manage the overall operation, integrating sensors and relays. Wiring diagrams detail these connections, highlighting how the timer and modules interact to maintain optimal performance, prevent overheating, and ensure smooth system operation, critical for reliability and energy efficiency in walk-in freezers.

3.3 Evaporator and Condenser Fan Motors

The evaporator fan motor circulates cold air, while the condenser fan motor dissipates heat. Wiring diagrams detail their connections to control modules, ensuring efficient operation and consistent temperatures. Proper wiring prevents overheating, ensuring reliable performance in walk-in freezers.

Installation and Wiring Guidelines

Installation requires robust junction boxes with tear-proof cable glands, ensuring all wiring is secure and protected. Adhere to guidelines for proper connections and sealing of electrical components to maintain safety and efficiency.

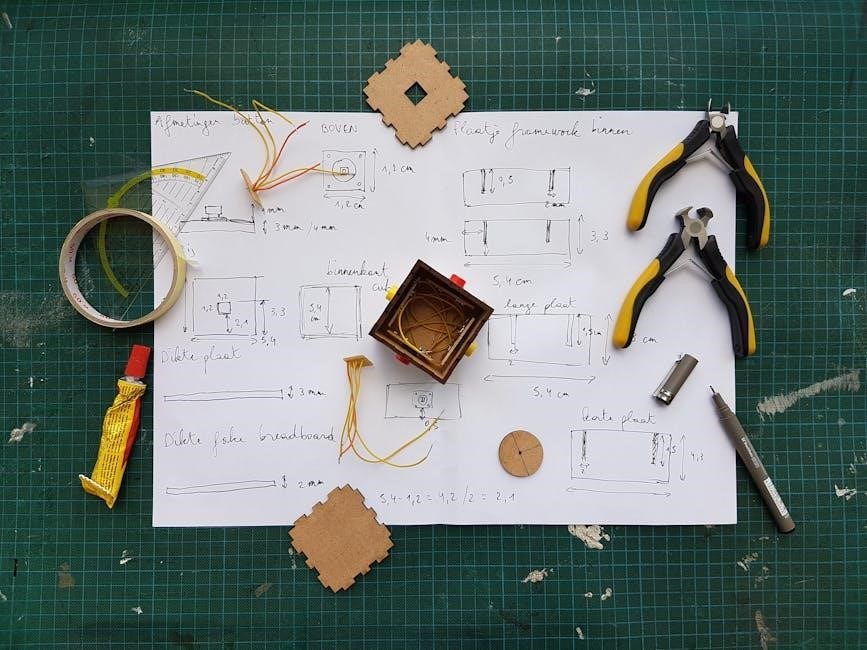

4.1 Step-by-Step Installation Process

Begin by reviewing the wiring diagram to identify components like compressors, defrost timers, and fan motors. Mount junction boxes securely, ensuring tear-proof cable glands are used for all connections. Connect power sources to the distribution board, following the diagram’s layout. Install temperature sensors and control modules, ensuring correct wiring to prevent malfunctions. Finally, test all circuits to confirm proper operation before finalizing the setup.

4.2 Safety Precautions for Wiring Walk-In Freezers

Always follow safety guidelines when wiring walk-in freezers. Ensure proper insulation of wires to prevent moisture damage. Use junction boxes with tear-proof cable glands for secure connections. Seal all electrical components to avoid contamination. Adhere to local electrical codes and use GFCI outlets for enhanced safety. Disconnect power before servicing. Consult a licensed electrician if unsure to avoid hazards.

Troubleshooting Common Electrical Issues

Identify faults in compressors, defrost timers, or wiring connections using diagrams. Check for overheating, short circuits, or power supply issues. Consult wiring diagrams for repair guidance to restore functionality safely.

5.1 Identifying Faults in the Wiring Diagram

Fault identification involves examining the wiring diagram for discrepancies or damage. Look for blown fuses, tripped breakers, or loose connections. Check if components like compressors or defrost timers are correctly represented. Cross-referencing the diagram with the actual setup helps pinpoint issues, ensuring accurate troubleshooting and minimizing downtime for the walk-in freezer system.

5.2 Common Problems and Their Solutions

Common issues include blown fuses, short circuits, or incorrect wiring. Solutions involve checking connections, ensuring proper voltage, and consulting the wiring diagram. Replacing faulty components like relays or sensors can resolve operational issues. Regular maintenance and adherence to the diagram’s guidelines help prevent recurring problems and ensure optimal walk-in freezer performance.

Legal and Safety Compliance

Walk-in freezer wiring must comply with local electrical codes and safety standards. Proper adherence ensures safe operation, preventing hazards like electrical fires or equipment damage, while meeting legal requirements.

6.1 Electrical Codes and Regulations

Walk-in freezer wiring diagrams must adhere to local and national electrical codes, such as the NEC, ensuring safe installations. Compliance with regulations like NFPA standards is crucial for fire safety and operational efficiency. Proper grounding, circuit protection, and conductor sizing are mandated to prevent hazards and ensure reliability in commercial refrigeration systems. Adherence is legally enforced.

6.2 Best Practices for Safe Electrical Connections

Ensure all connections are secure and protected from moisture using high-quality materials like tear-proof cable glands. Regularly inspect wiring for damage and tighten connections to prevent arcing. Use robust junction boxes with access holes for safe cable management. Follow industry standards for conductor sizing and grounding to minimize hazards. Always refer to the wiring diagram for precise connections and compliance.

Advanced Wiring Configurations

Advanced wiring configurations for walk-in freezers involve multi-evaporator systems and smart control integrations, ensuring efficient temperature management and remote monitoring capabilities for modern industrial applications.

7.1 Multi-Evaporator Systems

Multi-evaporator systems in walk-in freezers allow for precise temperature control across multiple compartments. These setups use advanced wiring diagrams to integrate multiple evaporators, ensuring efficient operation and minimizing energy consumption. Each evaporator operates independently, reducing the risk of system-wide failures and providing consistent cooling performance across different sections of the freezer.

7.2 Integration with Smart Control Systems

Integrating walk-in freezers with smart control systems enhances efficiency and monitoring. Advanced wiring diagrams enable seamless connectivity to IoT devices, allowing real-time temperature monitoring, automated defrost cycles, and energy optimization. These systems reduce manual oversight, ensure consistent performance, and provide data-driven insights for maintenance, improving overall operational efficiency and reducing energy consumption.

Tools and Resources for Wiring Diagrams

Specialized software and tools are essential for creating and interpreting walk-in freezer wiring diagrams, ensuring accurate installations and modifications. These resources streamline the electrical setup process.

8.1 Software for Creating Custom Wiring Diagrams

Dedicated software tools like wiring diagram creators simplify the design of custom walk-in freezer wiring diagrams. These programs allow users to draft, edit, and share detailed electrical layouts, ensuring precision and compliance with industry standards. They often include libraries of common symbols and components, making the creation process efficient and accessible even for complex systems.

8.2 Recommended Tools for Electrical Installation

Essential tools for installing walk-in freezer wiring include wire strippers, multimeters, and cable glands. These ensure safe and efficient connections. Robust junction boxes with tear-proof cable glands are also crucial for protecting wiring, while drain line heaters prevent icing. Proper tools guarantee compliance with electrical codes and long-term system reliability.

Maintenance and Upkeep

Regular inspection of electrical components, such as junction boxes and cable glands, ensures system longevity. Secure connections and check for wear or damage to prevent failures, adhering to safety codes and manufacturer guidelines.

9.1 Regular Inspection of Electrical Components

Regular inspection of electrical components in walk-in freezers ensures optimal operation. Check wiring connections, junction boxes, and cable glands for wear or damage. Verify that all components are securely fastened and that no signs of overheating or corrosion are present. This proactive approach helps prevent unexpected malfunctions and maintains efficiency, ensuring compliance with safety standards and manufacturer guidelines.

9.2 Preventive Maintenance Tips

Preventive maintenance for walk-in freezer wiring involves scheduled inspections, cleaning, and replacing worn-out components. Ensure all connections are tight and free from corrosion. Regularly test circuit breakers and fuses, and replace any damaged wiring. Lubricate moving parts and check thermal overload protectors. These practices minimize downtime, extend equipment lifespan, and ensure reliable operation of the freezer system.

Environmental Considerations

Environmental considerations involve optimizing energy efficiency and adopting eco-friendly wiring practices to reduce waste. Proper adherence to regulations ensures sustainable operation and minimizes the freezer’s carbon footprint.

10.1 Energy Efficiency in Walk-In Freezer Wiring

Energy efficiency in walk-in freezer wiring involves using high-efficiency motors and optimizing circuit designs. Proper insulation and smart controls reduce power consumption. Advanced wiring diagrams ensure minimal energy loss, promoting eco-friendly operation and cost savings.

10.2 Eco-Friendly Wiring Practices

Eco-friendly wiring practices for walk-in freezers include using recyclable materials and energy-efficient components. Proper cable management and insulation reduce heat loss and energy waste. These practices minimize environmental impact while maintaining performance, aligning with sustainable business goals.

Case Studies and Examples

Real-world applications of walk-in freezer wiring diagrams highlight successful installations in commercial kitchens and storage facilities, showcasing efficient electrical layouts and reduced downtime through clear circuit designs.

11.1 Real-World Applications of Walk-In Freezer Wiring Diagrams

Walk-in freezer wiring diagrams are essential in commercial kitchens, supermarkets, and large storage facilities. They ensure efficient electrical layouts, reducing downtime and enhancing safety. Real-world examples include installations in restaurants, warehouses, and retail spaces, where clear circuit designs simplify maintenance and troubleshooting, ensuring continuous operation and regulatory compliance.

11.2 Lessons Learned from Successful Installations

Successful walk-in freezer installations highlight the importance of proper grounding, secure connections, and using the correct wire gauge. Adherence to electrical codes ensures safety and efficiency. Regular inspections and preventive maintenance are crucial for long-term reliability. These practices minimize downtime and optimize performance, reinforcing the value of precise wiring diagram implementation in real-world applications.

Walk-in freezer wiring diagrams are essential for safe, efficient installations. Future trends include smart technologies and energy-efficient designs, enhancing performance and sustainability in commercial refrigeration systems globally.

12.1 Summary of Key Concepts

This guide covered essential aspects of walk-in freezer wiring diagrams, including components, symbols, installation, and troubleshooting. Emphasis was placed on safety, compliance, and efficiency, ensuring a comprehensive understanding for technicians and installers to maintain optimal freezer performance and adhere to electrical standards effectively.

12.2 Emerging Trends in Walk-In Freezer Wiring Technology

Emerging trends include the integration of smart control systems, energy-efficient wiring configurations, and eco-friendly practices. Advanced automation and IoT-enabled sensors optimize performance, reducing energy consumption. These innovations enhance safety, simplify maintenance, and ensure compliance with modern electrical standards, driving the evolution of walk-in freezer technology for sustainable and efficient operation.