The SEL-351S Relay offers advanced protection, monitoring, and control capabilities with IEEE C37.118 synchrophasors for wide-area system stability awareness and built-in Ethernet communication for simplified network integration and enhanced efficiency.

1.1. Specifications

The SEL-351S Protection System is designed to provide advanced protection, monitoring, and control features in a compact 3U chassis. It supports IEEE C37.118 synchrophasors for wide-area system stability awareness and includes built-in Ethernet for simplified communication. The relay offers screw terminal blocks for easy wiring and is compatible with a variety of applications, including directional overcurrent protection. Key features include overcurrent, voltage, and frequency protection elements, as well as loss-of-potential and directional logic for enhanced system reliability. The SEL-351S also supports advanced monitoring and control capabilities, making it ideal for modern electrical networks. Its design focuses on safety and efficiency, ensuring optimal performance in various operational environments.

- Compliant with IEEE C37.118 synchrophasor standards.

- 3U chassis for space-efficient installation.

- Screw terminal blocks for reliable connections.

- Built-in Ethernet for enhanced communication.

- Advanced protection and monitoring capabilities.

Installation

The SEL-351S requires careful mounting and wiring to ensure proper operation. Built-in Ethernet simplifies communication setup, while screw terminal blocks provide reliable connections. Follow manual guidelines for secure installation.

- Mount securely in a 3U chassis.

- Connect wires using screw terminal blocks.

- Configure Ethernet for network communication.

2.1. Mounting and Wiring

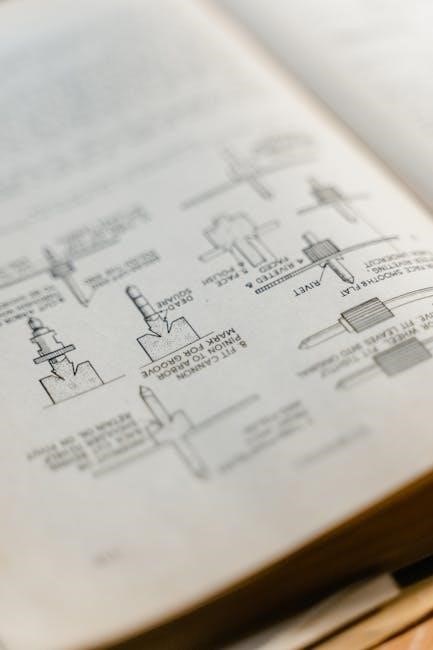

The SEL-351S Relay is designed for secure installation in a standard 3U chassis, ensuring reliable operation in various environments. Proper mounting involves securing the relay to the chassis using compatible hardware. Wiring connections are made via screw terminal blocks, which provide durable and straightforward connections. The built-in Ethernet port simplifies network communication setup, while the intuitive design minimizes wiring complexity. Refer to the instruction manual for detailed mounting and wiring diagrams. Ensure all connections are tightened securely to prevent loose contacts. The relay’s compact design and standardized connections make installation efficient. Always follow safety guidelines when handling electrical components to avoid potential hazards. Proper installation ensures optimal performance and longevity of the SEL-351S Relay.

2.2. Commissioning

Commissioning the SEL-351S Relay involves a series of steps to ensure proper operation and integration into the system. Begin by verifying all connections and settings according to the instruction manual. Power up the relay and check for any alarms or indicators of improper configuration. Configure the built-in Ethernet port for network communication, ensuring compatibility with IEEE C37.118 synchrophasors for wide-area system stability monitoring. Test protection elements, such as overcurrent and voltage monitoring, to confirm they function as intended. Validate control features, including trip and target logic, to ensure they respond correctly to system conditions. Use the provided software tools to verify settings and perform final testing. Always follow safety guidelines during commissioning to prevent potential hazards. Proper commissioning ensures the SEL-351S operates efficiently and reliably in its intended application.

Protection Elements

The SEL-351S provides comprehensive protection elements, including overcurrent, voltage, and frequency protection, along with advanced features like IEEE C37.118 synchrophasors for system stability and loss-of-potential detection.

3.1. Overcurrent, Voltage, and Frequency Elements

The SEL-351S incorporates advanced overcurrent, voltage, and frequency protection elements to ensure reliable operation in various power systems. The overcurrent protection includes adjustable settings for phase and ground faults, allowing precise coordination with system requirements. Voltage protection elements monitor undervoltage and overvoltage conditions, providing timely detection and response to abnormal voltage levels. Frequency protection ensures system stability by detecting deviations from the nominal frequency, crucial for maintaining power quality and preventing potential cascading failures. These elements are essential for protecting equipment and ensuring continuous operation in both normal and fault conditions. The SEL-351S also supports customizable settings, enabling users to tailor protection parameters to specific system needs. Together, these features enhance the overall reliability and safety of electrical systems by providing comprehensive monitoring and responsive protection mechanisms.

3.2. Loss-of-Potential and Directional Logic

The SEL-351S incorporates advanced loss-of-potential (LOP) and directional logic to enhance system protection and reliability. The LOP element detects the loss of voltage on one or more phases, which can indicate a bus fault or loss of supply, enabling the relay to respond appropriately. Directional logic ensures precise fault detection by determining the direction of current flow relative to voltage, critical for distinguishing between forward and reverse faults. This allows the relay to operate selectively, reducing unnecessary tripping and improving system stability. The directional element also supports phase and ground fault detection, ensuring comprehensive protection for various system configurations. Combined with customizable settings, these features provide robust protection for electrical systems, ensuring accurate and reliable operation under diverse conditions. The SEL-351S’s advanced logic enhances fault detection and system performance, making it a versatile solution for modern power systems.

Trip and Target Logic

The SEL-351S employs sophisticated trip and target logic to ensure precise and reliable operation during fault conditions. This logic determines when to issue a trip signal based on detected anomalies, such as overcurrent or voltage fluctuations, utilizing IEEE C37.118 synchrophasors for enhanced accuracy. The built-in Ethernet facilitates communication, enabling coordinated tripping across the network for efficient fault isolation. Customizable logic allows users to tailor trip conditions to specific system needs, optimizing performance. The SafeLock pushbuttons provide independent control for manual interventions, ensuring safe and deliberate actions. This advanced logic integrates seamlessly with other protection elements, offering comprehensive fault management. By combining these features, the SEL-351S delivers a robust solution for modern electrical systems, ensuring reliability and adaptability.

Communication Features

The SEL-351S offers advanced communication capabilities, including built-in Ethernet for seamless integration into modern network systems. This feature supports IEEE C37.118 synchrophasors, enabling wide-area system stability awareness and efficient data transmission. The relay also supports standard communication protocols, ensuring compatibility with SCADA systems and other networked devices. The Ethernet connection allows for remote monitoring, configuration, and control, enhancing operational efficiency. Additionally, the SEL-351S provides flexible communication options, including MODBUS TCP/IP and other industry-standard protocols, making it adaptable to various system requirements. These features ensure reliable and efficient communication, critical for real-time monitoring and control in electrical systems. By leveraging these capabilities, the SEL-351S simplifies network integration and enhances overall system performance, making it a versatile solution for modern protection and control applications.

Monitoring and Control Features

The SEL-351S provides comprehensive monitoring and control features, enabling precise oversight and management of electrical systems. It includes advanced metering capabilities for voltage, current, and power, allowing real-time monitoring of system performance. The relay also offers event recording and fault locating functionalities, which are essential for diagnosing and resolving issues quickly. Control features include independent SafeLock trip and close pushbuttons, ensuring safe and reliable operation. The large, easy-to-use operator controls simplify panel design and enhance usability. Additionally, the SEL-351S supports directional logic and load encroachment monitoring, providing detailed system insights. These features, combined with its robust protection elements, make the SEL-351S a powerful tool for maintaining system stability and reliability. By integrating monitoring and control into one device, the SEL-351S streamlines operations and reduces the complexity of system management.

Safety Precautions

Always prioritize personal safety and equipment protection when working with the SEL-351S Relay. Ensure the power is disconnected before performing any installation or maintenance tasks to avoid electrical hazards. Follow all instructions carefully to prevent material damage and ensure proper system operation. Use only recommended batteries, such as those from TYT, as specified in the manual, to maintain reliability and safety. Avoid using incompatible batteries, as this may lead to unpredictable behavior or damage. Adhere to all safety guidelines provided in the manual to safeguard your well-being and the integrity of the equipment. Failure to comply with these precautions may result in serious consequences. For further details, refer to the comprehensive safety section in the SEL-351S Instruction Manual.

Additionally, be aware of U.S. and foreign patents covering SEL products, as stated in the documentation, to ensure compliance with legal requirements.

Troubleshooting

Troubleshooting the SEL-351S Relay involves identifying and resolving issues efficiently. Always refer to the Instruction Manual for detailed diagnostic procedures and guidelines; Common issues may include communication errors, incorrect settings, or hardware malfunctions. Use built-in diagnostic tools and LED status indicators to identify faults. For example, check the Ethernet connection if communication issues arise, or verify settings if the relay does not respond as expected. Ensure all connections are secure and comply with the manual’s specifications. If problems persist, consult the troubleshooting section in the manual or contact SEL support for assistance. Adhering to these steps ensures optimal performance and minimizes downtime. Regular maintenance and updates, as outlined in the manual, can also prevent potential issues from arising. By following these guidelines, users can effectively troubleshoot and maintain the SEL-351S Relay.

The SEL-351S Relay is a versatile and advanced protection and control device designed to meet the demands of modern electrical systems. With its comprehensive suite of protection elements, communication capabilities, and user-friendly interface, it provides reliable performance and ease of operation. The built-in Ethernet and IEEE C37.118 synchrophasors enable wide-area system stability and simplified network integration. The detailed Instruction Manual ensures proper installation, configuration, and troubleshooting, making it accessible for both experienced professionals and new users. By combining advanced features with robust construction, the SEL-351S Relay is an essential tool for ensuring system reliability and efficiency. Its design and functionality make it a valuable asset for various industrial and utility applications, offering a balance of power and simplicity. Always refer to the manual for optimal use and adherence to safety guidelines, ensuring the device operates at its full potential.